- +966-504827632

CNC High Precision Turning Centers

Leading Manufacturers, Exporters, Wholesaler of AX 200 CNC High Precision Turning Center and AX 300 CNC High Precision Turning Center from .

| Business Type | Manufacturer, Exporter, Supplier |

Preferred Buyer From

| Location | All Countries |

Moving a step ahead in achieving even higher level of accuracy & precision, AX Series machines have been designed. Thus to cater increasing demand of market for multi-tasking with highest precision in turning and milling to deliver productivity solutions with reliability.

Features :

- Roller type LM Guideways for higher rigidity and accuracy to maximize productivity.

- Digital tailstock with option to replace with Sub-spindle.

- 1st and 2nd setup machining in single part clamping with better accuracy.

- Single piece slant bed architecture made out of high grade cast iron for maximal rigidity working at higher feed rates up to 35 m/min.

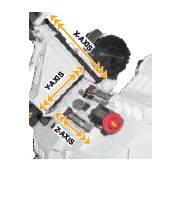

- Off center machining capability due to Y-Axis in turret.

- Linear Glass Scale delivering (6 μm) positioning with (3 μm) repeatability.

- Fully capable to interface with various other productivity improvement options for better output.

- Machining capability of angled surfaces and complex part machining.

(Main + Secondary) Electrospindle : Powerful electrospindle as standard, enclosed in headstock made out of closed grain casting and provided with provision for better heat dissipation.

- Hydraulically clamped C-axis disc brake to enable heavy duty and precision milling operations.

- Sub-spindle has Z-Axis movement to pick component from main spindle.

- Sub-spindle can work in synchronisation to main spindle for critical long shaft application.

| Business Type | Manufacturer, Exporter, Supplier |

Preferred Buyer From

| Location | All Countries |

Moving a step ahead in achieving even higher level of accuracy & precision, AX Series machines have been designed. Thus to cater increasing demand of market for multi-tasking with highest precision in turning and milling to deliver productivity solutions with reliability.

Features :

- Roller type LM Guideways for higher rigidity and accuracy to maximize productivity.

- Digital tailstock with option to replace with Sub-spindle.

- 1st and 2nd setup machining in single part clamping with better accuracy.

- Single piece slant bed architecture made out of high grade cast iron for maximal rigidity working at higher feed rates up to 35 m/min.

- Off center machining capability due to Y-Axis in turret.

- Linear Glass Scale delivering (6 μm) positioning with (3 μm) repeatability.

- Fully capable to interface with various other productivity improvement options for better output.

- Machining capability of angled surfaces and complex part machining.

(Main + Secondary) Electrospindle : Powerful electrospindle as standard, enclosed in headstock made out of closed grain casting and provided with provision for better heat dissipation.

- Hydraulically clamped C-axis disc brake to enable heavy duty and precision milling operations.

- Sub-spindle has Z-Axis movement to pick component from main spindle.

- Sub-spindle can work in synchronisation to main spindle for critical long shaft application.